PROGRESSIVE SURFACE SYSTEM P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PROGRESSIVE SURFACE SYSTEM P.LTD.

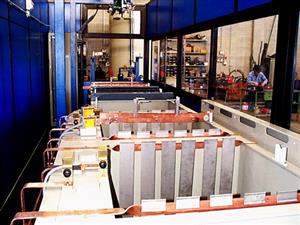

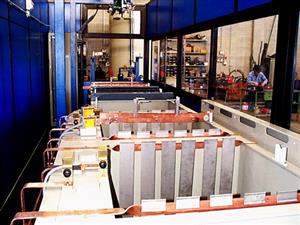

Electrolytic Cleaners

Our electrolytic cleaners are highly reliable and industry tested. They are suitable for removing standard surface contaminants (liquid, solids and particulates). Our cleaners can be used anodically and cathodically for ferrous metals (including steel) and non-ferrous metals. These cleaners work well in eradicating tenacious scale, grease, oxides, smut and similar debris to make your substrate process ready.

Alloy Plating

|

Alkaline Soak Cleaners

Effective cleaning dictates the performance of the subsequent processes in your system. These high performance cleaners remove standard surface contaminants like grease, shop dirt etc. Our products cater to a wide range of ferrous and non-ferrous metals. Since every metal needs to be cleaned differently, we offer a large number of metal specific cleaning variants in our portfolio. Surfaces are sure to appear bright and be ‘active’ after this process.

Anodizing Solutions

Description / Specification of Anodizing Solutions

We are involved in offering a wide range of Anodizing Solutions to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Anodizing Solutions. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Electrocoloring Products

Varying thicknesses of the oxide layer on anodized aluminium present the opportunity of electrolytically creating spectral/rainbow colors. Our chemicals are designed to evenly distribute the desired color on the entire article. Since Tin is actively used in this process, we also provide stabilizers to ensure that the desired color result is achieved in the electrocoloring bath.

Zinc Flake Coatings

Zinc Flake Coating is achieved by taking zinc and adding this to an inorganic binder. This creates a material that is functional in its performance and simple to apply. It has certain advantages over more traditional plating systems such as issues relating to component size, density problems and embrittlement can be avoided.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.